Stanesby, “Railways”, part 6

{77}

Carriages.—Railway carriages for the conveyance of passengers are usually very capacious, the bodies being

made to project over the wheels, which on ordinary lines seldom exceed three feet diameter. This arrangement is not

productive of danger, since the evenness of a railway, the comparatively low build of the carriages, and the great

weight of the iron wheels, axles, and framing under the body, prevent the liability of overturning. On account of the

rapid speed at which they travel, and the violent shocks to which they are occasionally subject, great strength of

construction is necessary; and the circumstance of several vehicles being linked together in one train renders the use

of an elastic apparatus for starting and stopping them essential. Elasticity in the traction is also necessary, in order

that the engine may not have to overcome the inertia of the whole train at the same instant, which would require much

more power than suffices, when they are started, to keep the whole in motion.

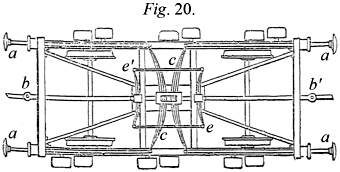

Various contrivances are in use for this

purpose, but fig. 20 may serve to give a correct idea of the principles on which they all act. It represents

the ground-plan of a passenger-carriage, the body being removed. The frame, which is outside the wheels, is supported on

lapped springs, which, by brass bushes or bearings, rest on the ends of the axles, they being extended beyond the

wheels, and accurately turned, for that purpose. a a a a are buffers, or disks of wood or metal,

sometimes covered with cushions, fixed on the ends of long rods which pass through the frame and along the sides to the

ends of the long springs c c, which are capable of moving towards each other when pushed by the rods, but

are prevented by stops on the frame from moving in the opposite direction. The centre being allowed to slide backwards

and forwards, both springs are brought into action by an impulse given to either end. All the buffers in a train being

placed at the same height and width, they come into contact when the carriages run towards one another in stopping

suddenly, and the jerk is by them communicated to the springs c c, whose elasticity allows so much motion as

to prevent any injurious shock to the carriage. The traction apparatus, or that by which the carriages are drawn

forward, consists of rods passing through the frame at b b′, and connected, in a manner which it is

unnecessary to describe, with the small springs e′ e, which also act together, the centre of e

pressing against the cross-bar of the carriage-frame as an abutment, when the pull is from b, and that of

e′, in the like manner, when the traction is in the direction of b′. The connection between

the different carriages often consists of a jointed bar of iron, which is disunited, when necessary, by the removal of a

pin. Chains are sometimes used, and occasionally united by a peculiar kind of screw, which draws the carriages so close

that their buffers come in contact. In some carriages the same springs serve both for traction and buffing, and spiral

or helical springs are not unfrequently applied to the purpose. Axle-guides, fixed to the framing, are used to keep the

axles square; but a more elastic construction of carriage, in which the axles have sufficient play to enable them to

adapt themselves to a curved track, and the springs for bearing the weight, drawing, and buffing, are made of an

unusually light character, is being introduced by Mr. Adams, with great promise of success. The ordinary first-class

carriages convey eighteen passengers, having a treble body, with six seats in each compartment; and the second-class, of

similar make, carry twenty-four passengers. Those on the Great Western Railway, which are mostly on six wheels, are much

larger, some of the second-class vehicles seating seventy-two persons. Open carriages, in which the passengers stand,

are frequently used for short stages. Waggons for goods and cattle, trucks for the conveyance of stage-coaches and

private carriages, and horse-boxes, are all mounted on springs, but their buffing apparatus is often very simple and

inelastic. The weight of the ordinary passenger-coaches, when empty, is from three to five tons.

Various contrivances are in use for this

purpose, but fig. 20 may serve to give a correct idea of the principles on which they all act. It represents

the ground-plan of a passenger-carriage, the body being removed. The frame, which is outside the wheels, is supported on

lapped springs, which, by brass bushes or bearings, rest on the ends of the axles, they being extended beyond the

wheels, and accurately turned, for that purpose. a a a a are buffers, or disks of wood or metal,

sometimes covered with cushions, fixed on the ends of long rods which pass through the frame and along the sides to the

ends of the long springs c c, which are capable of moving towards each other when pushed by the rods, but

are prevented by stops on the frame from moving in the opposite direction. The centre being allowed to slide backwards

and forwards, both springs are brought into action by an impulse given to either end. All the buffers in a train being

placed at the same height and width, they come into contact when the carriages run towards one another in stopping

suddenly, and the jerk is by them communicated to the springs c c, whose elasticity allows so much motion as

to prevent any injurious shock to the carriage. The traction apparatus, or that by which the carriages are drawn

forward, consists of rods passing through the frame at b b′, and connected, in a manner which it is

unnecessary to describe, with the small springs e′ e, which also act together, the centre of e

pressing against the cross-bar of the carriage-frame as an abutment, when the pull is from b, and that of

e′, in the like manner, when the traction is in the direction of b′. The connection between

the different carriages often consists of a jointed bar of iron, which is disunited, when necessary, by the removal of a

pin. Chains are sometimes used, and occasionally united by a peculiar kind of screw, which draws the carriages so close

that their buffers come in contact. In some carriages the same springs serve both for traction and buffing, and spiral

or helical springs are not unfrequently applied to the purpose. Axle-guides, fixed to the framing, are used to keep the

axles square; but a more elastic construction of carriage, in which the axles have sufficient play to enable them to

adapt themselves to a curved track, and the springs for bearing the weight, drawing, and buffing, are made of an

unusually light character, is being introduced by Mr. Adams, with great promise of success. The ordinary first-class

carriages convey eighteen passengers, having a treble body, with six seats in each compartment; and the second-class, of

similar make, carry twenty-four passengers. Those on the Great Western Railway, which are mostly on six wheels, are much

larger, some of the second-class vehicles seating seventy-two persons. Open carriages, in which the passengers stand,

are frequently used for short stages. Waggons for goods and cattle, trucks for the conveyance of stage-coaches and

private carriages, and horse-boxes, are all mounted on springs, but their buffing apparatus is often very simple and

inelastic. The weight of the ordinary passenger-coaches, when empty, is from three to five tons.

Locomotive Engines.—Since the successful adoption of locomotive steam-engines on the Liverpool and

Manchester Railway, improvements have followed closely upon one another, but they have been chiefly of a minor

character, when compared with that of tubing the boiler, which formed the distinguishing feature of the Rocket engine.

Stephenson built several engines shortly after the competition in which the Rocket had proved victorious, retaining this

arrangement, but having the machinery disposed in a different manner. The cylinders were placed in a box beneath the

chimney, and the piston-rods moved horizontally under the boiler, working two cranks formed on the axle of the

hind-wheels, which were then made the largest. The boiler and machinery were attached to a massive frame, the sides of

which were outside the wheels, and rested, by means of springs and brass bearings, on the ends of the axles. Bearings

outside the wheels have this decided advantage over inner ones—which are, nevertheless, preferred by some

engineers—that the ends of the axles may be turned

away to so small a diameter as materially to diminish the friction, without the risk of breakage which would attend the

reduction of the axle within the wheels. The superior economy of large engines becoming evident from experience, it was

deemed advisable to add a third pair of wheels, which were made small, like the fore-wheels, and placed under the

fire-box end of the machine. The flanges on the two pair of small wheels being sufficient to guide the machine,

Stephenson removed them from the central or driving pair, which thus

{78}

became mere rolling or propelling wheels, and were relieved from the lateral strains arising from the flange coming in

contact with the rail at curves and switches; such strains having been found injurious to the cranked axle and the

machinery connected with it. Some engine-builders still retain all the flanges, from an idea of greater security. The

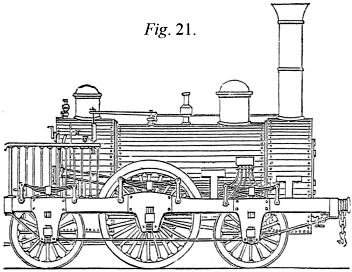

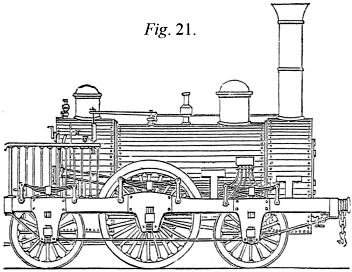

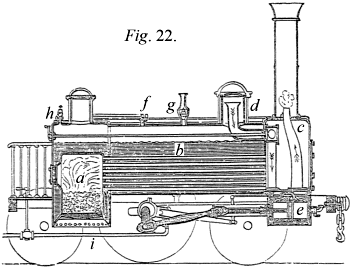

following figures may give some idea of the locomotive engine in this improved state, in which form it is now in use

upon most of the railways in this country, and several on the Continent and in America. Fig. 21 is an

elevation, and fig. 22 a longitudinal section, in which many minute details are omitted, for the sake of

distinctness.

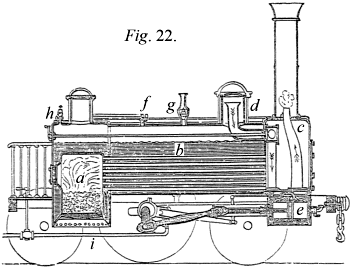

a is the fire-box, usually formed of copper, and surrounded by an outer casing of iron, leaving a space of three

or four inches all round, which is filled with water, and forms part of the boiler. The door by which the fire is

supplied with coke is made of two iron plates, with a space of a few inches between them, to prevent the radiation of

heat. Coke is carried in the tender,—a supplementary vehicle attached to the back of the engine. The

fire-box is usually open at the bottom, to allow the free access of air, so that cinders fall through the bars upon the

road,—a circumstance sometimes productive of accident. As there is very little water above the flat top of the

fire-box , a fusible plug is inserted in it, to act as a safety-valve in the event of the water becoming too low, and

leaving it dry. The tubes through the boiler b for the passage of flame and heated air are now always made of

brass, which is found much more durable than copper. They vary in number in different engines, from about ninety to a

hundred and fifty or upwards, being frequently less than an inch and a half in diameter. The power of generating steam,

which is the measure of efficiency in a locomotive engine, depends much upon judicious tubing, it being desirable to

deprive the heated air of its caloric as completely as possible before leaving the boiler. The chief practical limit to

the reduction of the tubes, and consequent increase of their number and extent of surface, is their liability to become

choked with cinders and ashes carried into them by the draft. Boilers are frequently tubed to such an extent that from

four to six hundred square feet of heated metal is exposed to the water, in addition to the area of the fire-box itself.

An important feature in a locomotive boiler is its security from bursting, because, as the tubes are much weaker than

the external casing of the boiler, they are almost certain to give way first, and the bursting of one or two tubes is

rarely productive of more serious consequence than extinguishing the fire, and thereby causing a gradual stoppage of the

machine.

a is the fire-box, usually formed of copper, and surrounded by an outer casing of iron, leaving a space of three

or four inches all round, which is filled with water, and forms part of the boiler. The door by which the fire is

supplied with coke is made of two iron plates, with a space of a few inches between them, to prevent the radiation of

heat. Coke is carried in the tender,—a supplementary vehicle attached to the back of the engine. The

fire-box is usually open at the bottom, to allow the free access of air, so that cinders fall through the bars upon the

road,—a circumstance sometimes productive of accident. As there is very little water above the flat top of the

fire-box , a fusible plug is inserted in it, to act as a safety-valve in the event of the water becoming too low, and

leaving it dry. The tubes through the boiler b for the passage of flame and heated air are now always made of

brass, which is found much more durable than copper. They vary in number in different engines, from about ninety to a

hundred and fifty or upwards, being frequently less than an inch and a half in diameter. The power of generating steam,

which is the measure of efficiency in a locomotive engine, depends much upon judicious tubing, it being desirable to

deprive the heated air of its caloric as completely as possible before leaving the boiler. The chief practical limit to

the reduction of the tubes, and consequent increase of their number and extent of surface, is their liability to become

choked with cinders and ashes carried into them by the draft. Boilers are frequently tubed to such an extent that from

four to six hundred square feet of heated metal is exposed to the water, in addition to the area of the fire-box itself.

An important feature in a locomotive boiler is its security from bursting, because, as the tubes are much weaker than

the external casing of the boiler, they are almost certain to give way first, and the bursting of one or two tubes is

rarely productive of more serious consequence than extinguishing the fire, and thereby causing a gradual stoppage of the

machine.

Owing to the limited size of the boiler, the steam which collects in the upper part is mixed with spray from the water.

A steam-chamber d is therefore added, in which it becomes free from the spray, and then enters the steam-pipe

that passes through the smoke-box c to the cylinders or engines at e. A throttle-valve in this pipe is

placed under the command of the engineer by a rod passing through the boiler and terminating in a handle connected with

a graduated scale at the back of the engine. By this the supply of steam to the cylinders is regulated or cut off when

necessary. Eccentrics for working the slide-valves, which admit steam alternately to each side of the piston, are fixed

on the main crank-axle; and in some engines two pair are used, one for working in common, and the other when the engine

runs backwards. The steam cylinders are usually twelve or thirteen inches diameter, and eighteen inches stroke; and the

driving-wheels of the engine from five to seven feet diameter, the small wheels being three or four feet.

The pipe shown in the section passing from the cylinders to the chimney is the blast-pipe for the exit of waste steam,

its upper end being tapered to give greater effect to the jet. At the top of the chimney a wire-gauze cap is frequently

fixed to arrest sparks and small cinders which are often thrown up by the strong draft, and have been the occasion of

many destructive fires; but a more effectual remedy has been recently introduced, consisting of a grating at the bottom

of the chimney, which stops the cinders before they are affected by the steam jet.—f and g are

safety-valves held down by springs, the former only being under the control of the engine-driver.—h is a

steam-whistle, which, by its shrill sound, warns persons working on the line of the approach of an

engine.—i is one of two feed-pipes, communicating between the water-tank in the tender and small

forcing-pumps under the boiler, which are worked by the engine, and ensure an equable supply of water in the boiler.

Valves for regulating this supply, handles for reversing the motion of the machine, steam and water gauges, and numerous

other conveniences are added, being placed within reach of the engine-driver, when on the platform at the back of the

fire-box. In order to economise the heat by checking its radiation, the boiler is coated with wood, and sometimes

flannel is placed between them. The steam-dome and similar parts are double, the space between the inner and outer

casing answering the same purpose. The tender, and sometimes the engine itself, is supplied with powerful brakes, to

arrest the motion of the wheels when necessary. Some of the carriages also have them, and handles for working them are

placed within reach of the guards.

Stationary Engines.—Locomotive engines are very expensive to work, on account of their necessarily limited

dimensions, and the rapid action of the working parts; while the addition of their own weight to the load to be

conveyed, and the injury they cause to the rails, form additional disadvantages, from which stationary engines are

exempt. But the smaller cost of working stationary engines is met by a serious drawback,—the friction of the rope

used to convey their power to the carriages, and of the sheaves or pulleys upon which it is supported. The use of

stationary engines is generally confined to those parts of a railway which are too steep to be conveniently worked by

locomotives; but a very ingenious

{79}

application of them has been introduced for working the London and Blackwall Railway, which appears to possess some

important advantages for the working of a short line with numerous stations, as the through passengers are not delayed

by the stoppage of the train at intermediate stations; each station having a distinct carriage, which stops and starts

independently of the rest. To avoid the inconvenience attending the use of ropes is the object of the “atmospheric

railway,” in which the power of stationary steam-engines is communicated to the train by means of an exhausted

tube, instead of a rope. The diminished risk of collision is one advantage attending the use of stationary instead of

locomotive engines.

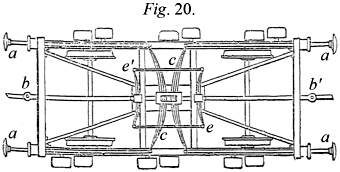

Various contrivances are in use for this

purpose, but fig. 20 may serve to give a correct idea of the principles on which they all act. It represents

the ground-plan of a passenger-carriage, the body being removed. The frame, which is outside the wheels, is supported on

lapped springs, which, by brass bushes or bearings, rest on the ends of the axles, they being extended beyond the

wheels, and accurately turned, for that purpose. a a a a are buffers, or disks of wood or metal,

sometimes covered with cushions, fixed on the ends of long rods which pass through the frame and along the sides to the

ends of the long springs c c, which are capable of moving towards each other when pushed by the rods, but

are prevented by stops on the frame from moving in the opposite direction. The centre being allowed to slide backwards

and forwards, both springs are brought into action by an impulse given to either end. All the buffers in a train being

placed at the same height and width, they come into contact when the carriages run towards one another in stopping

suddenly, and the jerk is by them communicated to the springs c c, whose elasticity allows so much motion as

to prevent any injurious shock to the carriage. The traction apparatus, or that by which the carriages are drawn

forward, consists of rods passing through the frame at b b′, and connected, in a manner which it is

unnecessary to describe, with the small springs e′ e, which also act together, the centre of e

pressing against the cross-bar of the carriage-frame as an abutment, when the pull is from b, and that of

e′, in the like manner, when the traction is in the direction of b′. The connection between

the different carriages often consists of a jointed bar of iron, which is disunited, when necessary, by the removal of a

pin. Chains are sometimes used, and occasionally united by a peculiar kind of screw, which draws the carriages so close

that their buffers come in contact. In some carriages the same springs serve both for traction and buffing, and spiral

or helical springs are not unfrequently applied to the purpose. Axle-guides, fixed to the framing, are used to keep the

axles square; but a more elastic construction of carriage, in which the axles have sufficient play to enable them to

adapt themselves to a curved track, and the springs for bearing the weight, drawing, and buffing, are made of an

unusually light character, is being introduced by Mr. Adams, with great promise of success. The ordinary first-class

carriages convey eighteen passengers, having a treble body, with six seats in each compartment; and the second-class, of

similar make, carry twenty-four passengers. Those on the Great Western Railway, which are mostly on six wheels, are much

larger, some of the second-class vehicles seating seventy-two persons. Open carriages, in which the passengers stand,

are frequently used for short stages. Waggons for goods and cattle, trucks for the conveyance of stage-coaches and

private carriages, and horse-boxes, are all mounted on springs, but their buffing apparatus is often very simple and

inelastic. The weight of the ordinary passenger-coaches, when empty, is from three to five tons.

Various contrivances are in use for this

purpose, but fig. 20 may serve to give a correct idea of the principles on which they all act. It represents

the ground-plan of a passenger-carriage, the body being removed. The frame, which is outside the wheels, is supported on

lapped springs, which, by brass bushes or bearings, rest on the ends of the axles, they being extended beyond the

wheels, and accurately turned, for that purpose. a a a a are buffers, or disks of wood or metal,

sometimes covered with cushions, fixed on the ends of long rods which pass through the frame and along the sides to the

ends of the long springs c c, which are capable of moving towards each other when pushed by the rods, but

are prevented by stops on the frame from moving in the opposite direction. The centre being allowed to slide backwards

and forwards, both springs are brought into action by an impulse given to either end. All the buffers in a train being

placed at the same height and width, they come into contact when the carriages run towards one another in stopping

suddenly, and the jerk is by them communicated to the springs c c, whose elasticity allows so much motion as

to prevent any injurious shock to the carriage. The traction apparatus, or that by which the carriages are drawn

forward, consists of rods passing through the frame at b b′, and connected, in a manner which it is

unnecessary to describe, with the small springs e′ e, which also act together, the centre of e

pressing against the cross-bar of the carriage-frame as an abutment, when the pull is from b, and that of

e′, in the like manner, when the traction is in the direction of b′. The connection between

the different carriages often consists of a jointed bar of iron, which is disunited, when necessary, by the removal of a

pin. Chains are sometimes used, and occasionally united by a peculiar kind of screw, which draws the carriages so close

that their buffers come in contact. In some carriages the same springs serve both for traction and buffing, and spiral

or helical springs are not unfrequently applied to the purpose. Axle-guides, fixed to the framing, are used to keep the

axles square; but a more elastic construction of carriage, in which the axles have sufficient play to enable them to

adapt themselves to a curved track, and the springs for bearing the weight, drawing, and buffing, are made of an

unusually light character, is being introduced by Mr. Adams, with great promise of success. The ordinary first-class

carriages convey eighteen passengers, having a treble body, with six seats in each compartment; and the second-class, of

similar make, carry twenty-four passengers. Those on the Great Western Railway, which are mostly on six wheels, are much

larger, some of the second-class vehicles seating seventy-two persons. Open carriages, in which the passengers stand,

are frequently used for short stages. Waggons for goods and cattle, trucks for the conveyance of stage-coaches and

private carriages, and horse-boxes, are all mounted on springs, but their buffing apparatus is often very simple and

inelastic. The weight of the ordinary passenger-coaches, when empty, is from three to five tons.

a is the fire-box, usually formed of copper, and surrounded by an outer casing of iron, leaving a space of three

or four inches all round, which is filled with water, and forms part of the boiler. The door by which the fire is

supplied with coke is made of two iron plates, with a space of a few inches between them, to prevent the radiation of

heat. Coke is carried in the tender,—a supplementary vehicle attached to the back of the engine. The

fire-box is usually open at the bottom, to allow the free access of air, so that cinders fall through the bars upon the

road,—a circumstance sometimes productive of accident. As there is very little water above the flat top of the

fire-box , a fusible plug is inserted in it, to act as a safety-valve in the event of the water becoming too low, and

leaving it dry. The tubes through the boiler b for the passage of flame and heated air are now always made of

brass, which is found much more durable than copper. They vary in number in different engines, from about ninety to a

hundred and fifty or upwards, being frequently less than an inch and a half in diameter. The power of generating steam,

which is the measure of efficiency in a locomotive engine, depends much upon judicious tubing, it being desirable to

deprive the heated air of its caloric as completely as possible before leaving the boiler. The chief practical limit to

the reduction of the tubes, and consequent increase of their number and extent of surface, is their liability to become

choked with cinders and ashes carried into them by the draft. Boilers are frequently tubed to such an extent that from

four to six hundred square feet of heated metal is exposed to the water, in addition to the area of the fire-box itself.

An important feature in a locomotive boiler is its security from bursting, because, as the tubes are much weaker than

the external casing of the boiler, they are almost certain to give way first, and the bursting of one or two tubes is

rarely productive of more serious consequence than extinguishing the fire, and thereby causing a gradual stoppage of the

machine.

a is the fire-box, usually formed of copper, and surrounded by an outer casing of iron, leaving a space of three

or four inches all round, which is filled with water, and forms part of the boiler. The door by which the fire is

supplied with coke is made of two iron plates, with a space of a few inches between them, to prevent the radiation of

heat. Coke is carried in the tender,—a supplementary vehicle attached to the back of the engine. The

fire-box is usually open at the bottom, to allow the free access of air, so that cinders fall through the bars upon the

road,—a circumstance sometimes productive of accident. As there is very little water above the flat top of the

fire-box , a fusible plug is inserted in it, to act as a safety-valve in the event of the water becoming too low, and

leaving it dry. The tubes through the boiler b for the passage of flame and heated air are now always made of

brass, which is found much more durable than copper. They vary in number in different engines, from about ninety to a

hundred and fifty or upwards, being frequently less than an inch and a half in diameter. The power of generating steam,

which is the measure of efficiency in a locomotive engine, depends much upon judicious tubing, it being desirable to

deprive the heated air of its caloric as completely as possible before leaving the boiler. The chief practical limit to

the reduction of the tubes, and consequent increase of their number and extent of surface, is their liability to become

choked with cinders and ashes carried into them by the draft. Boilers are frequently tubed to such an extent that from

four to six hundred square feet of heated metal is exposed to the water, in addition to the area of the fire-box itself.

An important feature in a locomotive boiler is its security from bursting, because, as the tubes are much weaker than

the external casing of the boiler, they are almost certain to give way first, and the bursting of one or two tubes is

rarely productive of more serious consequence than extinguishing the fire, and thereby causing a gradual stoppage of the

machine.